Functional coatings are a cornerstone of the manufacturing industry, offering tailored solutions to enhance the performance, durability, and aesthetics of a wide range of products. These coatings are engineered to provide specific properties, such as corrosion resistance, thermal insulation, electrical conductivity, and abrasion protection, depending on the application.

Primers

Functional coating primers are essential in the manufacturing industry, as they provide a critical foundation for enhancing the performance and durability of various surfaces. Our primers are engineered to improve adhesion, corrosion resistance, and surface protection. By creating a robust bond between the substrate and the topcoat, functional coating primers help extend the lifespan of products and reduce maintenance needs. Additionally, they can be tailored with specialized properties, such as heat resistance, electrical conductivity, or chemical protection, to meet the unique demands of different applications.

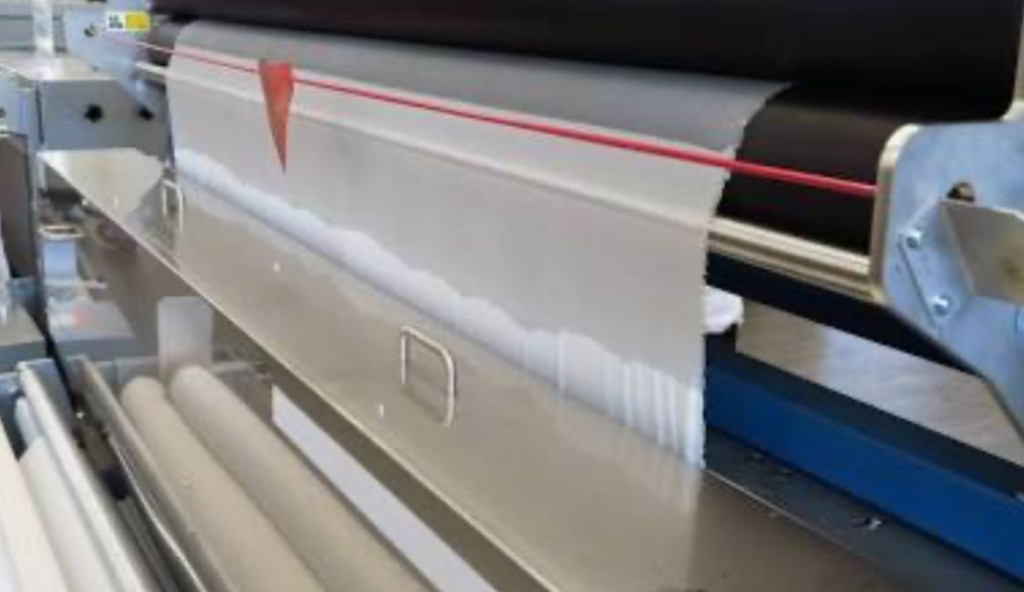

Print Receivers

Functional coating print receivers are a vital innovation in the manufacturing industry, enabling high-quality and precise printing on various substrates. These specialized coatings are designed to enhance the adhesion, durability, and vibrancy of printed materials. By optimizing surface properties, print receivers facilitate uniform ink absorption and improved resolution, even on challenging surfaces like plastics, metals, or glass. Additionally, they can be engineered with unique characteristics such as chemical resistance, moisture protection, or UV stability, ensuring the longevity and functionality of printed designs.

Abrasion resistant

Abrasion-resistant functional coatings offer enhanced protection and durability for surfaces subjected to wear and tear. These coatings are specifically engineered to resist scratches, scuffs, and mechanical damage. By improving the lifespan and performance of components, abrasion-resistant coatings reduce maintenance costs and downtime, contributing to operational efficiency. Additionally, these coatings can be tailored with advanced properties, such as chemical resistance or thermal stability, to meet the unique demands of specialized environments.

Metallization

Metallization functional coatings play a pivotal role in the manufacturing industry by enabling the deposition of a thin metallic layer onto diverse substrates such as plastics, ceramics, and glass. These coatings impart critical properties like enhanced conductivity, improved heat resistance, and electromagnetic interference shielding. Applications range from creating reflective surfaces in optical devices to producing lightweight, conductive components for advanced electronics. Additionally, metallization coatings contribute to product aesthetics by providing a sleek, metallic finish while maintaining material integrity.

Functional coatings can incorporate advanced features like chemical resistance, anti-fouling properties, or even self-healing capabilities, aligning with the demands of modern technology and sustainability. Their adaptability and innovative potential make functional coatings indispensable in driving progress across diverse manufacturing sectors.

Contact info@hbdynamics.com so we can help you choose the best functional coating for your products.